| |

|

Fully automated CT inspection system "HeiDetect XS CT"

|

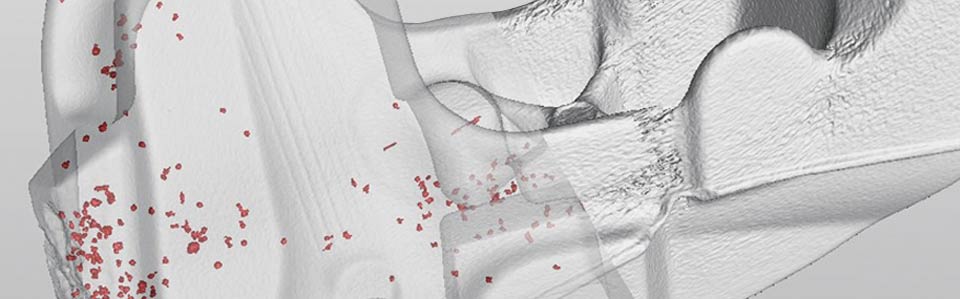

HeiDetect

XS CT is a fully automated inline CT inspection system for

workpieces of varying size and weight. The system consists

of a compact X-ray enclosure with high-performance X-ray

tubes and the Fraunhofer X-ray camera system, the XEye 4020.

The fully automated inspection of the 3D data is performed

using the Fraunhofer PIDA software. This versatile

inspection system from Heitec PTS GmbH adapts perfectly to

your individual requirements. This applies both to

integration in an existing material flow and communication

with the production IT system.

HeiDetect XS CT can also be loaded directly from a handling

system supplied by the customer. The intake opening for the

handling systems can be positioned and configured flexibly. Optionally, both the X-ray tubes and the

detectors can also be fitted on one axis system. This allows

for adjustment of the focus-to-detector distance and the

focus-to-object distance depending on the workpiece to be

inspected.

Secure, flexible and

efficient system technology

The gripper fingers of the robot, and where applicable, the

component pick-up by the transport system, can be adapted to

the respective product and are thus the only parts to be

replaced during a product change. Other functions such as

lasering and labelling can easily be integrated.

The detector from the Fraunhofer EZRT shows no signs of

degradation, replacement will not be necessary until it has

been in use for at least ten years.

|

|

|

|

|

The following operating modes are possible with HeiDetect XS

CT: |

|

PIDA Axial CT Robot: The

system will be equipped with a 6-axis industry robot

according to the customer´s wishes. |

|

PIDA Axial CT: The

inspection cabin is operated via a handling system provided

by the customer. |

|

Inspection system (without

robot or conveyor technology) |

|

Length |

2,000 mm |

|

Width |

1,300 mm |

|

Height |

1,020 mm |

|

Weight |

approx. 1.5 t |

|

Inspection system |

|

|

Type |

XEye 4020 |

|

Active Surface |

400 - 200 mm |

|

Pixel size |

50 μm - 400 μm

(edge length) |

|

COMET MXR-160HP/11 (160

kV, 1.8 kW) |

|

COMET MXR-225HP/11 (225

kV, 1.8 kW) |

(Other tubes on request) |

|

|

Fully automated 3D

data analysis |

|

Fraunhofer PIDA (Process

Integrated Defect Analysis) |

|

KUKA LBR iiwa |

7 kg or 14 kg |

|

KUKA Agilus |

up to 10 kg |

(Other robot

manufacturers and sizes

on request) |

|

Part dimensions for

XS version |

|

Diameter |

max. 150 mm

around rotational

axis |

|

Length |

max. 350 mm |

|

Weight |

depends on the

used robot |

|

|