| |

|

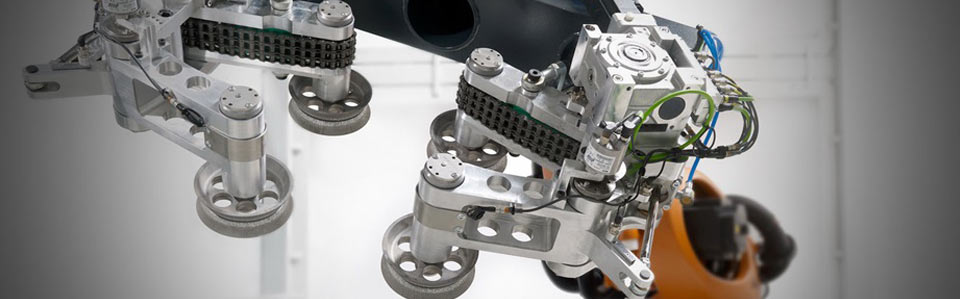

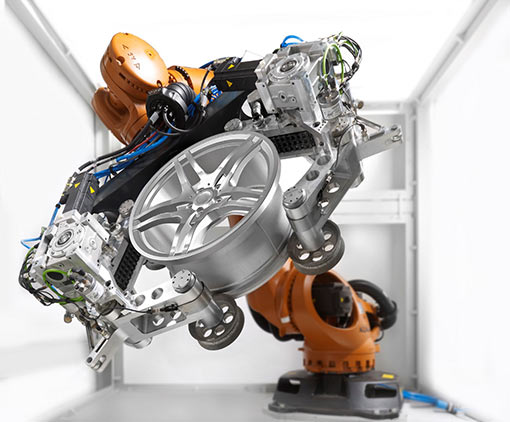

Fully automated wheel test facility "HeiDetect Wheel Robot"

|

The

HeiDetect Wheel Robot wheel test facility achieves an

extremely high throughput thanks to its industrial robot and

is therefore ideal for inline operation in the mass

production of cast aluminium wheels. Several areas of the

wheel can be tested in one testing position by using a

larger detector. This benefit means that the number of

handling steps can be reduced, thus shortening the test time

for each wheel.

HeiDetect Wheel Robot is a fully automatic wheel test

facility and, through the integration of the

ISAR

image evaluation software and the

XEye

image evaluation software and the

XEye

detector developed by the

Fraunhofer Institute for Integrated Circuits, allows for an almost

pseudo error-free evaluation with stable image quality. Due to the

efficient processing of images, casting errors such as

shrink holes, pores, cavities and foreign matter can be

detected and classified in the

range of 3% of the radiographed wall thickness. Large areas of oxide can be

detected from a size of 1% of the wall thickness.

detector developed by the

Fraunhofer Institute for Integrated Circuits, allows for an almost

pseudo error-free evaluation with stable image quality. Due to the

efficient processing of images, casting errors such as

shrink holes, pores, cavities and foreign matter can be

detected and classified in the

range of 3% of the radiographed wall thickness. Large areas of oxide can be

detected from a size of 1% of the wall thickness.

Further benefits are the automatic wheel

detection and the incorporation of barcodes. This enables the

alignment of the wheels to be specified and monitor the test

results. The HeiDetect Wheel Robot wheel test facility from

Heitec PTS GmbH meets the latest requirements for the group of

wheels and handles wheel sizes from 13” to 24”.

The

ISAR

evaluation software offers an ergonomic

Windows-based graphic user interface via which the test

parameters can be set specifically for customers. Key data

can be transmitted via an existing operating data

acquisition system.

evaluation software offers an ergonomic

Windows-based graphic user interface via which the test

parameters can be set specifically for customers. Key data

can be transmitted via an existing operating data

acquisition system.

Specially prepared test results are transmitted to

production in real-time, thereby enabling trend analysis and

continuous product quality optimization, aiming to minimize

scrapping.

Reliable and efficient

systems engineering

The small installation space and full enclosure mean that

incorporation into the production process is possible, even

in extreme conditions in mass production. The wheel gripper

is designed so that wheels with a faulty rim flange can also

be tested. Further functions such as lasing and labelling

can also be incorporated without any problems. As the

detector from the Fraunhofer Institute for Integrated

Circuits shows an extremely low rate of degradation, a

replacement will not be required for at least 10 years or

so.

Data sheet HeiDetect Wheel Robot

|

|

|

|

|

Few test positions due to

large detector area (400 x 200 mm) |

|

Permanent, stable image

quality due to a degradation-free detector |

|

Spokes and hub can be

captured with a single image |

|

No distortion and

brightness variation, no reparametrization necessary |

|

Almost pseudo error-free

detection thanks to state-of-the-art Fraunhofer ISAR image

processing |

|

New wheel types can be set

up within a few minutes during the test operation |

|

Offline remote

parametrization during the operation |

|

A single test program for

multiple systems |

|

Additional degree of

freedom when positioning the wheels by using a 6-axis robot |

|

Simple maintenance of the

gripper thanks to access from outside the system |

|

Use of a standard

industrial robot for test piece handling |

|

Test system |

|

|

Length |

4.200 mm |

|

Width |

2.980 mm |

|

Height |

2.900 mm |

|

Weight |

approx. 12 t |

|

Max. test piece weight |

40 kg |

|

Wheel diameter |

13 to 24 inches |

|

Max. wheel width |

up to 15 inches |

|

Detector |

|

|

Type |

XEye 4020 |

|

Active surface |

400 x 200 mm |

|

Pixel size |

100 - 400 μm |

|

Manufacturer |

Comet |

|

Tube voltage |

160 kV |

|

Tube performance |

600 / 1.000 W |

|

Detector |

XEye 4020 |

|

Fully automatic data

analysisg |

|

|

|